Resources

View our library of brochures, galleries, faq, webinars + more.

Your browser is out of date.

You are currently using Internet Explorer 7/8/9, which is not supported by our site. For the best experience, please use one of the latest browsers.

We can design an enclosure that complements your marking system and fits your part sizes, marking field requirements, and any other system aspect specific to your application. Enclosures can also be designed to implement a variety of accessories for part feeding and handling, automation, and more.

Laser mark safely with an enclosure designed specifically for your marking application. Certified class I enclosures adhere to federal protective housing guidelines and prevent light and radiation from escaping. These preventative measures make them safe to use without protective eyewear. They also help protect your laser and reduce the amount of dust and debris it encounters in your environment.

If you have a marking application that requires a custom laser enclosure, let's discuss your needs and how we can design and build a laser marking machine just for you. Call us at 847-647-7117 for more information.

This Class 1 system features an automatic conveyor feed and a horizontally-mounted laser that is used to mark four hydraulic hex fittings in two locations simultaneously. The operator loads parts onto a secured fixture and actuates the system, feeding the parts to the marking station where they are all marked.

After the marking is completed, the conveyor moves forward and drops the parts into a tote. As the fixture rotates to the bottom of the conveyor, another fixture is pulled into the marking field, and the operation repeats.

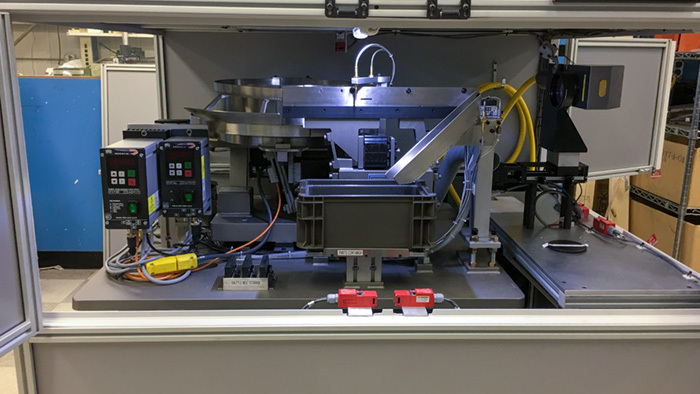

For this application, an automatic bowl feed and conveyor were installed within a Class 1 enclosure, along with a laser mounted horizontally to mark round electrical fittings. The feed system is adjustable to allow for multiple sizes of electrical fittings.

Parts are batch-loaded into the bowl feed by an operator and the doors of the enclosure are closed and secured. The automatic cycle is initiated and the laser system feeds and marks each part at the rate of 2 to 3 seconds per part.

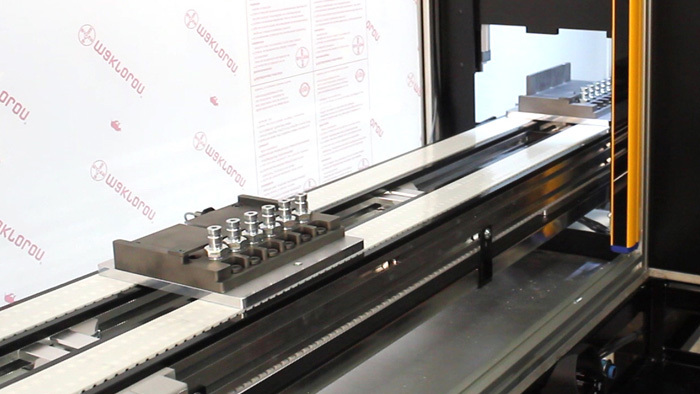

Although large parts can be marked by a laser without an enclosure, an enclosure may be preferred or needed to operate the laser safely in an open working environment. For this application, a large enclosure was designed and built to fit

bedframe rails up to 105” long.

The bed frame rails are placed lengthwise onto a support fixture and the dual doors are manually closed. Inside the enclosure, the part is marked lengthwise on the flat surface of the bed rail.

Dual marking heads were built within this custom class I laser marking system to minimize the need to move the 2000 pound drill bits as they were being marked.

The lasers marked the drill bits in two different places simultaneously. One was mounted underneath the part at a fixed location to mark radially on the top surface of the bit. The second laser was mounted horizontally on a programmable Z- and X-axis slide to mark into the surface of the drill bit.

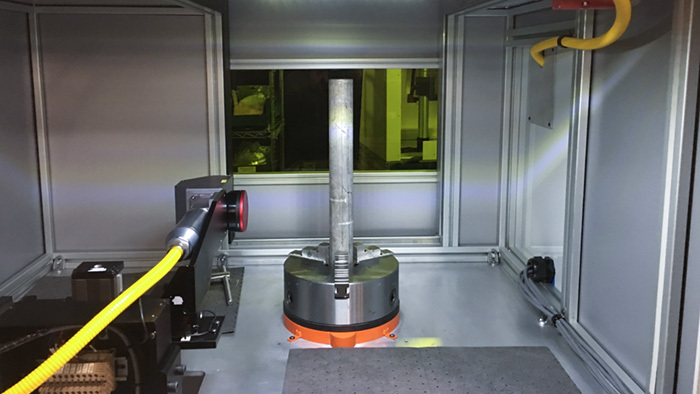

Designed to mark pressure control valves weighing up to 100 pounds each, this Class 1 laser marking system houses a vertical rotary fixture and a laser marking head that is mounted horizontally on a programmable X- and Z-axis.

Parts are loaded from the top of the system and the marking enclosure includes a side door for easy access and maintenance. The laser moves along the programmable X- and Z-axis to mark around the diameter of pressure control valves of various sizes.

To mark a 2D data matrix onto four plastic lighting shells simultaneously, we designed and built a Class 1 laser marking system with two laser heads and a custom fixture.

After the lighting shells are loaded manually onto a four-position rotating support fixture, the automatic door closes and the marking cycle is initiated.

At GT SCHMIDT, we design, build, and implement marking solutions that help manufacturers leave a lasting mark on their products, their companies, and their industries.

Learn More About Us