Pin Marking

WHAT IS DOT PEEN PIN MARKING?

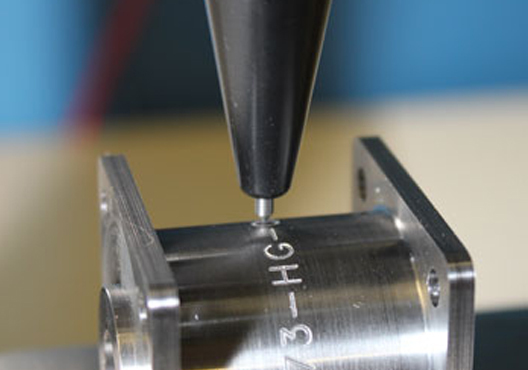

Pin marking (also referred to as stylus marking and dot peen marking) is the use of a pneumatic or electromechanically controlled carbide tip assembly that strikes the surface of a part in a sequence of dots to produce a permanent mark. Depending on the type of pin assembly, power settings, and marking speed parameters, pin marking can create light, moderate, or deep marks on the surface of parts. Pin marking is ideal for most metals and some hard plastics.

GT SCHMIDT offers several pin marking machine options including column-mounted desktop machines, portable hand-held systems, or integratable marking heads. All pin marking machines can be equipped with a variety of accessories and custom options or customize to fit your exact needs.

Is pin marking the right marking technology for you? Tell us about your marking application and we'll tell you if pin marking is the best solution for your needs or if a different technology is right for you.

Our Pin Marking Machines & Components

Answers to Common Pin Marking Questions

WHAT ARE THE BENEFITS OF DOT PEEN MARKING?

Dot peen pin marking can provide high-speed, permanent marks that are durable enough to withstand even the harshest environments. They can make shallow and deep marks, even on hard metals.

Pin marking technology is very versatile and there are many options available for almost any marking application and work environment.

WHAT PARTS AND MATERIAL ARE BEST FOR PIN MARKING?

Pin marking machines are best used on metal parts and some hardened plastics.

CAN I MARK ROUND AND FLAT PARTS WITH A PIN MARKER?

Styliner marking machines are computer-controlled and are specifically designed to accommodate a variety of part shapes and sizes. They are capable of marking flat, round, curved, convex, and concave parts, as well as irregular and delicate surfaces.

Our pin marking machines can also be equipped with rotary chuck fixtures for rotating round parts during the marking cycle. A variety of fixturing is available for round and flat parts.