Roll Marking

WHAT IS ROLL MARKING?

Pneumatic and hydraulic roll marking machines use a rolling motion - either of the part itself or of the stamp that produces the mark - to mark round, cylindrical, and flat parts in high volumes. Roll marking is an economical solution for applications that have high tonnage requirements. Choose from a variety of roll marking machines and tooling to roll mark round, cylindrical, and flat parts.

Roll marking has many benefits:

- Mark round or flat parts.

- Less operating noise than marking presses.

- No impact damage to parts.

- Quick tooling changes.

- Low equipment costs relative to heavy presses.

- Can be configured with part-feeding systems.

- Long-lasting stamps.

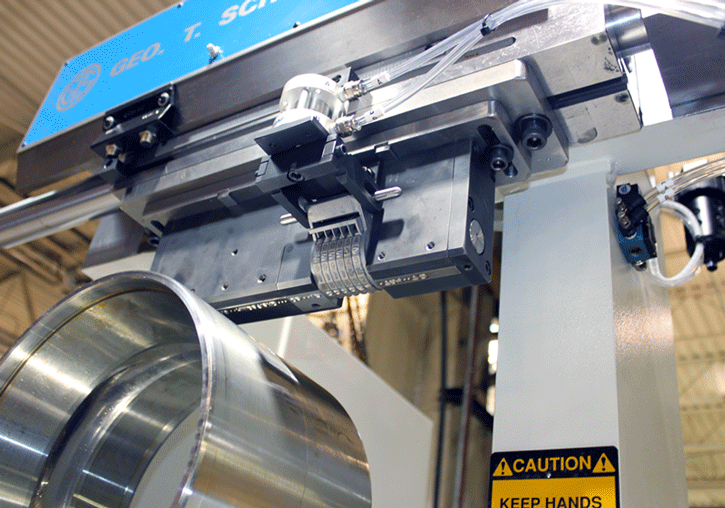

ROLL MARKING MACHINES

GT SCHMIDT offers three different types of roll marking machines to to provide traditional marking solutions for a wide variety of needs and applications. A variety of holders are available to accomodate type and dies. We also have a selection of part feeders available to automate the part-feeding process.

need a custom solution?

Our in-house design and engineering department has a full range of services and support to ensure that your marking application is successful.

Why GT SCHMIDT?

At GT SCHMIDT, we design, build, and implement marking solutions that help manufacturers leave a lasting mark on their products, their companies, and their industries.

Learn More About Us

made in usa since 1895

125 years of experience

installation & follow-up support